Statistical Process Control (SPC):

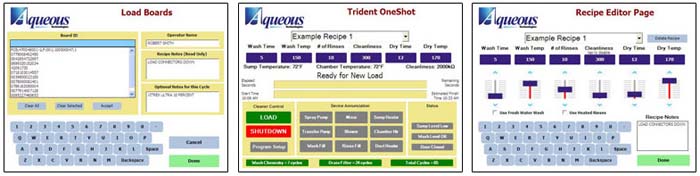

Trident features a comprehensive Statistical Process Control (SPC) system. Alpha/Numeric recipe names, process times and temperatures, set and actual rinse resistivity levels and other valuable data are stored automatically. Built in assembly barcode scanning allows all of the SPC data to be tied to a specific assembly serial/lot number. Advanced search features allow the SPC data to be viewed on screen, sent to a wireless printer, exported via USB and viewed via network protocols.

The following process data is automatically captured:

• Assembly serial number

• Date and time of batch (start and completion)

• Programmed wash solution temperature

• Actual wash solution temperature

• Maximum quantity of programmed rinse cycles

• Actual quantity of rinse cycles

• Programmed cleanliness value

• Actual cleanliness value

• Pass and fail cleanliness status

• Programmed drying time

• Actual drying time

• Programmed drying temperature

• Actual drying temperature

• Operator name

• Operator notes

• Equipment notifications (if any)

Users may utilize the aSPC software's advanced search capability to search for specific assemblies that have previously been cleaned and tested. Users may enter an individual assembly serial number, date ranges, operator names, recipe names or pass/fail status for access to specific SPC data records. Additionally, users may view or print all SPC data records. Trident's aSPC software is also equipped with an export feature, allowing all SPC data to be exported as an .XLS file for import into Excel® or other data capturing software. Trident's aSPC software stores the captured data in an industry standard SQL database for easy data integration into third-party software. Trident's aSPC software is compatible with 1D and 2D USB barcode scanners.